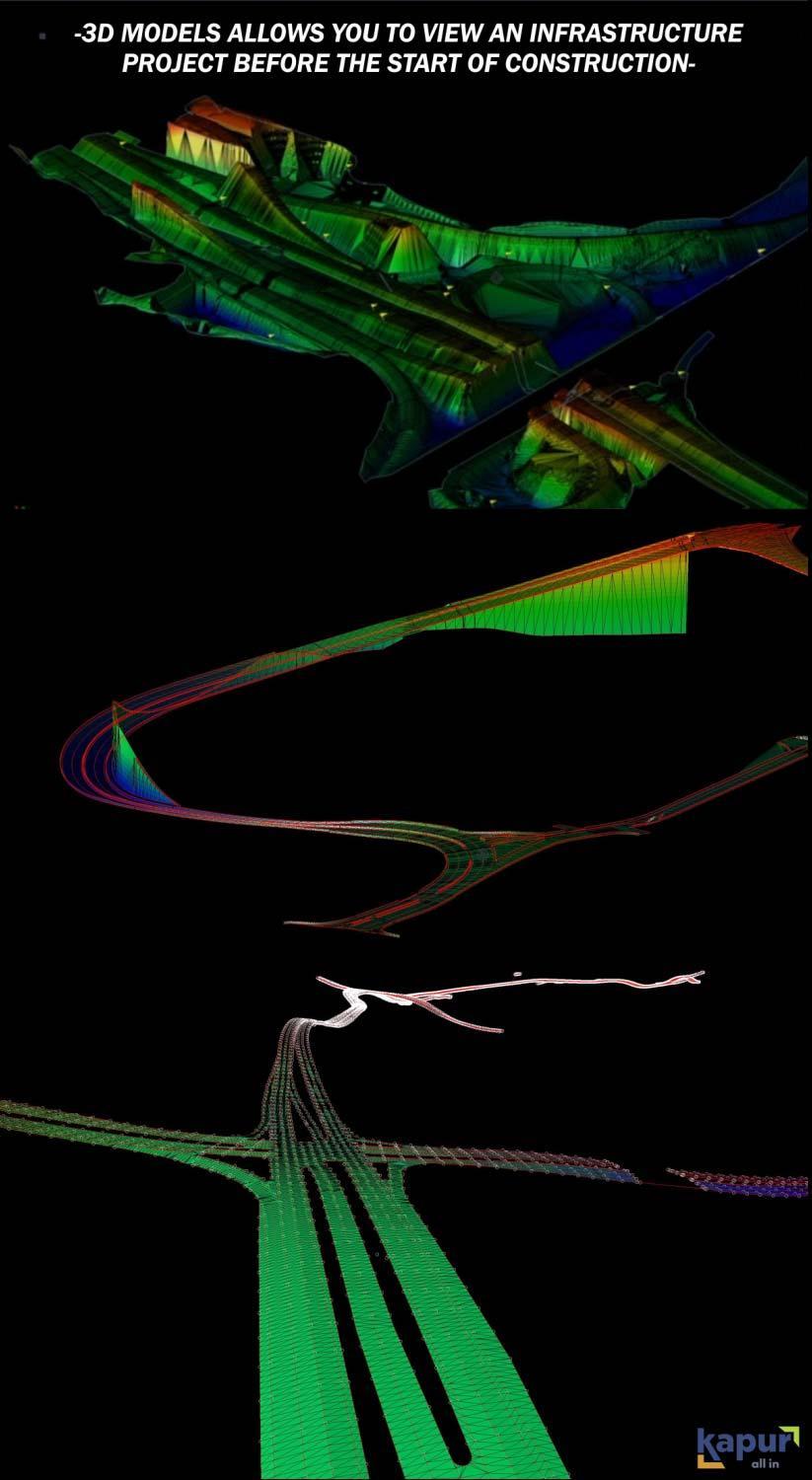

3D Modeling

With the ever-evolving technology that is being utilized in the infrastructure industry, one of the most beneficial advancements in the last few years to Kapur’s team has been the development of 3D modeling. Since these technologies, Kapur uses these 3D programs for plans, specs, and crucial information to be combined into a singular file with full detail. By combining the information in this way, our entire team can have a more complete picture of how everything will conform in the three-dimensional world that we live in. Allowing our team to have the complete picture to view is beneficial. It allows our team to view projects before they begin, identify and correct errors faster, increase production time, have easily shareable files, a second set of eyes, efficient collaboration between teams, and quick feedback time.

What are the 3D models that Kapur builds?

Kapur’s 3D modelers will take a multiple two-dimension flat set of plans and create them into the three-dimensional space before any infrastructure project has even started. To do this, the modeler will bring all the proposed plans from the designers (paving grades, cross-sections, and typical sections; as well as wall, drainage, and bridge plans) and bring them together to create one working, all-inclusive 3D model. By putting all this information into one 3D model, it brings all the pieces to life clearly for all to see. It ensures everyone has efficient collaboration between teams, clients, and contractors involved with the project. This one single file may be used by all involved in building the infrastructure project.

Specific uses of 3D models

There are a growing number of ways that these 3D technologies are utilized by our clients. These 3D models all aid in making the building process more efficient and accurate. Being able to create and reference a three-dimensional model has a wide assortment of practical uses, listed below are a few examples.

GPS Machine Control – This type of 3D model is sent to GPS Rovers that can read the model and allow the field crews to see where grading is needed.

Survey Staking – Survey crews use this type of 3D model so they can accurately locate where stakes should be placed.

Stringless Paving – With this advancing technology becoming the preferred paving method, this has become especially useful. The stringless pavers are equipped with the technology to read the 3D models Kapur creates and identify where to precisely pave, all under the crew’s supervision and knowledge of the model.

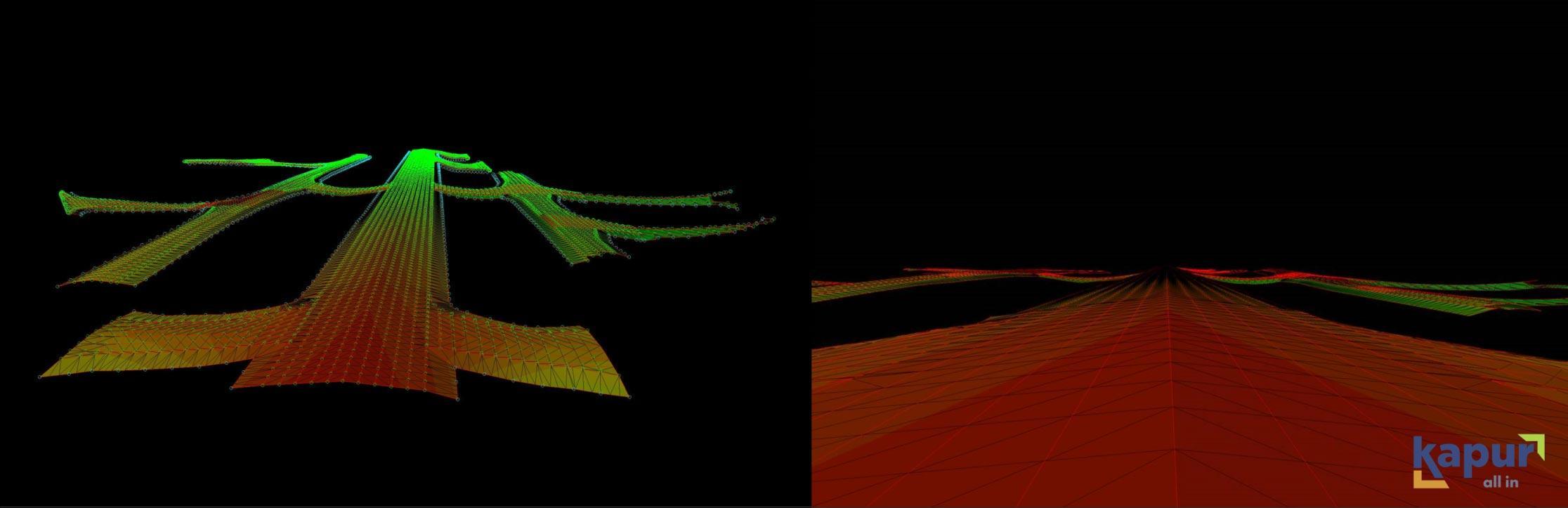

Earthwork Quantities – This 3D technology can effectively compute volumes of the area and compare them with the proposed subgrades. By creating a singular, detailed model in the three-dimensional space, both modelers and contractors benefit and can work together with ease.

Benefits of 3D models

There are numerous benefits when using one of Kapur’s 3D models during an infrastructure project. Below is a list of benefits that can save time and cost to a project.

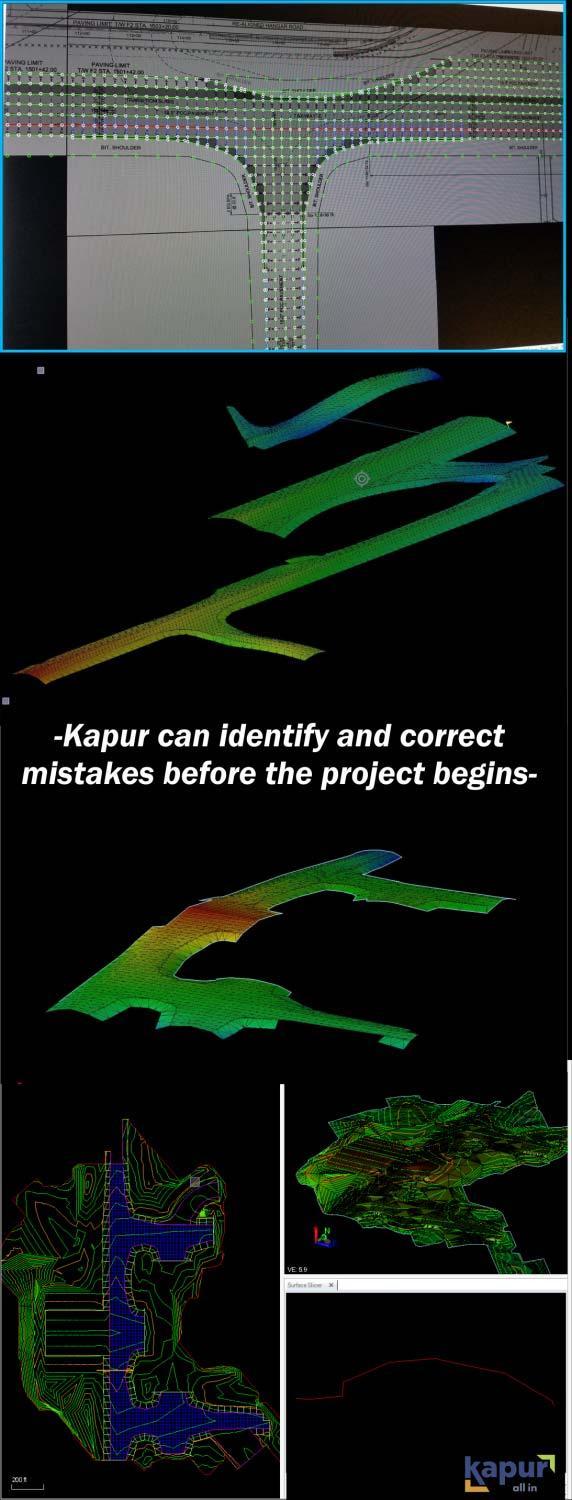

- IT ALLOWS OUR TEAM TO IDENTIFY AND CORRECT ERRORS EASILY

- ALLOWS ACCESS TO VIEW PROJECTS BEFORE THEY ARE BUILT

- INCREASE PRODUCTION TIME

- ALLOWS FILES TO BE SHARED EASILY

- A SECOND SET OF EYES TO FIND ERRORS

- ALLOWS FOR QUICKER FEEDBACK TIME

- ALLOWS EVERYONE TO WORK FROM ONE 3D MODEL

- EFFICIENT COLLABORATION BETWEEN STAFF, CLIENTS, AND CONTACTORS

- MODEL INTEROPERABILITY – (the ability for multiple software programs and hardware to communicate with one another) – This is beneficial knowing that many different programs are used within one infrastructure project

- TURNING DESIGNER METADATA INTO DETAILED LOGISTICS – Most plans do not include things like ADA sidewalk or curb transitions because these are state-regulated specs, and don’t need to be modeled out in the designer model, as they are usually referenced in the plan within the details or standards section. However, by including these details into the complete 3D model, we are further creating a complete picture and making even greater strides to prevent error or confusion. For example, there was a revision made to a plan that would possibly affect a nearby ADA regulated ramp. By having the entire area modeled, including the ramp itself, these changes could be implemented while knowing how this would affect the ADA regulated ramp. Having the 3D model allowed the contractor and team to see any other potential issues quickly and eliminates any potential oversight.

Why use 3D models?

Kapur continues to have an enthusiastic willingness to explore innovative technologies to benefit infrastructure projects, like the use of 3D modeling. These advancing technologies ensure that our models, layout, and earthwork are precise and accurate. It further allows us the ability to use countless software programs and hardware. Kapur modelers, creating the ability to look at a three-dimensional space before any work takes place allows for a new perspective on the data and allows for any revisions to be made with ease. By looking at the complete 3D picture, we are setting our Kapur team, our clients, contractors, and projects, up for success.